November 2023

Tooling up for Tesla

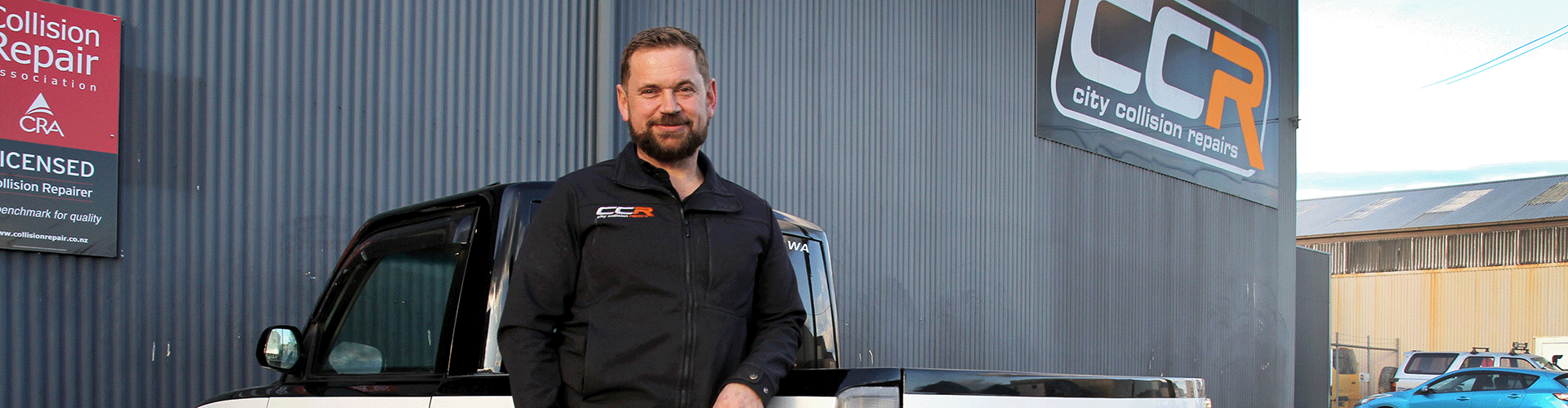

Call it a leap of faith. Call it an eye for an opportunity. But for MTA member Chris Greaney taking on a Tesla repair contract has been a bold move that’s paid off.

And he’s a great example to other members of how embracing green technology can be a blueprint for success.

Chris has been repairing cars for a few decades and saw an opportunity with Tesla that would give century-old family business Napier City Collision Repairs an edge over the competition.

It did cost a chunk of cash, as Tesla are fussy about the tools he needed.

The chassis machine was the wrong brand, the spot welder was the wrong brand and even the measuring machine and the paint system didn’t meet Tesla specifications.

On the upside, the new gear isn’t just for Tesla's, it’s capable of repairing a range of car makes.

And it wasn’t just the equipment that needed updating.

“It was a lot of online training and each technician as well as managers and estimators had to do different modules with Tesla to be able to fix the cars,” Chris says.

Now Chris is the only one in the central North Island who’s allowed to get genuine Tesla parts and have access to the service manuals.

“It is an agreement between Tesla and me that for my level of investment they will refer as much work as possible to me.”

Chris is proud of the fact that he has a five out of five rating for customer surveys.

All in the timing

Once replacement parts are specified and priced, the repair programme tells Chris what glue to use, how many rivets the job requires and what kind of rivets.

“I repaired one myself the other day and I was replacing a rear quarter and to replace that section there were spot welds, MIG plug welds, MIG weld joins, four different types of rivets, structural adhesive all the way around and an M flange on the wheel arch.

“There were six attachment methods for one panel, whereas five years ago there were plug welds and spot welds and that was it,” Chris says.

All the different systems are needed because on a Tesla they are joining dissimilar metals.

“The guys on the shop floor have evolved and a new entrant into our industry needs to be a lot more educated, our aim as an industry should be to attract people who are on the verge of, [deciding] should they go to university or should they get a trade,” Chris says.