July 2025

Kiwi EV Training Goes Global

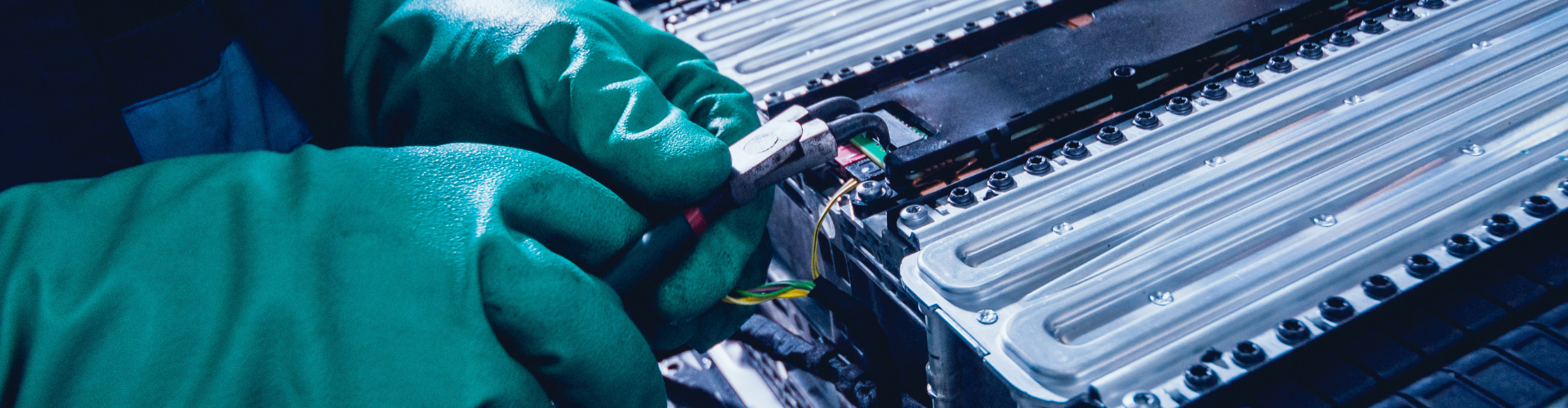

Otago Polytech has tackled the knowledge gap by creating a series of training programmes to teach automotive techs how to find and repair faults on EVs.

Now the programmes have gone international with a USA connection and former MTA region chair Hamish Miller was at the helm of the course's development.

Now the programmes have gone international with a USA connection and former MTA region chair Hamish Miller was at the helm of the course's development.

Hamish is the Auto/Eng Academic Leader at Otago Polytechnic, where he and staff found the best way to solve the problem was to build their own EV training from scratch.

“EVs are supposed to be a sustainable product and being able to fix them makes them more sustainable and puts them back on the road,” he says.

“It also meant we were getting into EV training right at the beginning of the changes to the industry. We could see there were going to be more and more EVs parked up under trees because they couldn’t be fixed.”

What Hamish and his team have designed are five safety levels of training, with level four giving apprentices the know-how to do a basic diagnosis, while the level five certificate teaches how to carry out repairs and maintenance on the high voltage components.

The lessons are online with a block course practical component that is based in Dunedin.

Exporting knowledge

From its home-grown roots, the courses are having international impact, with Heartland Community College in Bloomington, Illinois sending their trainers to Dunedin to be trained.

Heartland discovered the training courses after doing some online research and got in touch with Hamish to see if it would fit with their existing training.

“They reached out to us after discovering what we were doing online and we popped them into one of our classes online as an observer,” Hamish says.

Heartland loved what they saw and quickly got things moving organising funding, through IGen, an Illinois green network, to bring Heartland staff to Dunedin.

They also flew Hamish and some of the Polytech staff over to Illinois so they could get an idea of what they were trying to achieve and to canvass for more enrolments.

“We went with the proviso that we would take on ten tutors and train them up, but after the tour we had 20 signed up,” Hamish says.

“It was like getting into automotive tourism.”

Now there are further global opportunities coming up, with Hamish fielding enquiries from a training organisation with links to the BYD factory in China.